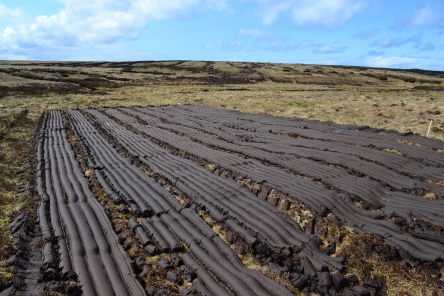

Yes, all these posts about peats may become a little tiresome – but just imagine how it feels going out there all the time!

The script out there just now, is filling bags with peats and piling them into the trailer! I think the trailer takes about 30-33 of these 25kg bags, that originally held sheep feeding stuff.

I filled a few bags, but didn’t help with loading them onto the trailer, due to my broken/dislocated finger. Instead, I got to annoy my father and brother by taking pictures of them!

Think that’s four loads of peats home, maybe another two or three to go. Getting them home within 3 weeks of them being cut is impressive – I don’t remember us ever doing that before but the weather has been very good and the peats have dried quickly. They should all be home by the end of the week!

And if you’re going to leave me smart-alex comments about how we could fit more in the trailer, should be using a tarasgeir etc, etc – don’t bother!